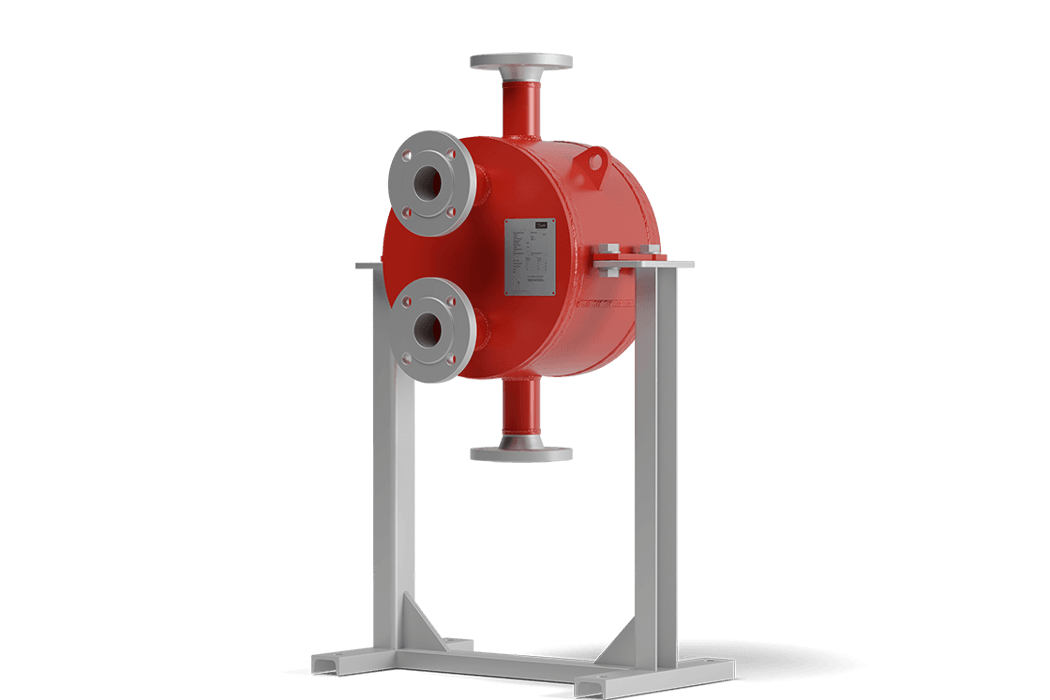

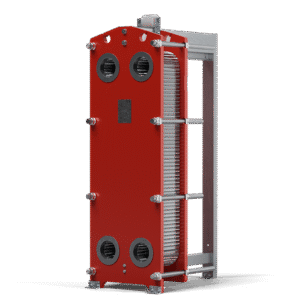

Welded heat exchangers

Product Description

Key Features & Benefits

Handles Extreme Conditions

Designed for aggressive media, extreme temperatures, and very high pressures.

Excellent for Condensation & Steam

An ideal choice for condensation duties and perfect for heating clean fluids with steam.

High Shock & Fatigue Resistance

Highly resistant to thermal shocks and pressure fatigue, perfect for cyclic duties.

Adaptable Designs

Available in bolted or fully welded designs to suit different maintenance and pressure needs.

Robust Construction

Frames and shells designed according to international pressure equipment standards (PED/ASME).

Effective CIP Cleaning

Fully welded types can be cleaned effectively using Cleaning-in-Place (CIP) systems.

Technical Specifications

Connection Sizes

From DN25 to DN300 (1" to 12")

Design Standards

FEA, PED 2014/68/EU (EN13445), and ASME Sec VIII, Div. 1.

Plate Materials

AISI 304/316, Titanium (others on request).

Shell Material

Carbon Steel or Stainless Steel.

Max Working Pressure

Up to 40 bar (580 psi).

Max Working Temperature

Up to 400°C (752°F) for fully welded types.

Installation & Control

Robust Integration

Designed for permanent integration into demanding industrial piping systems.

High-Pressure Mounting

Requires a solid foundation and proper support due to high operating weights and pressures.

Cleaning Method

Fully welded units rely on CIP (Cleaning-in-Place); bolted types can be opened mechanically.

Process Control

Performance is managed by system flow, temperature, and pressure controls.

Durability Focus

Installation prioritizes minimizing stress and vibration for long-term reliability.

Use Cases

- Oil & Gas Coolers

- Petrochemical Industry

- Power Generation

- Heavy Industry

- Marine & Offshore

Product brochure

User Manual

Related Products

Related products

- Heat Exchangers

Brazed heat exchangers

- Heat Exchangers

Gasketed heat exchangers