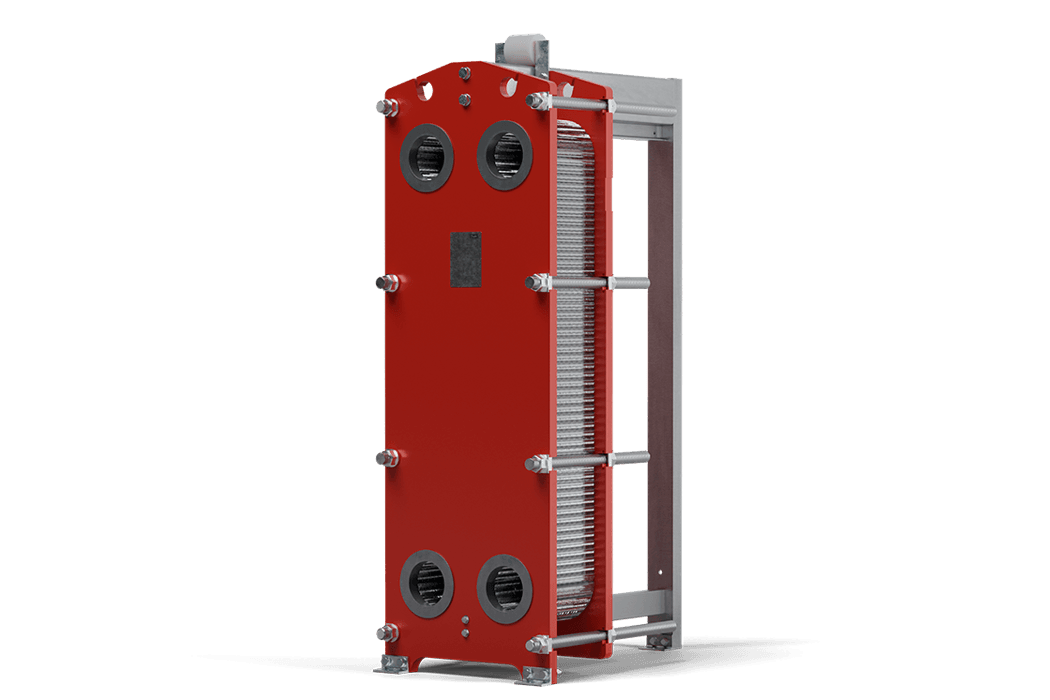

Gasketed heat exchangers

Gasketed heat exchangers

SONDEX® standard plate heat exchangers are ideal for a wide range of applications across different industries. With innovative design and advanced technology, they offer high efficiency and great value. A large plate portfolio allows full customization to meet specific requirements for any application

Product Description

Key Features & Benefits

Wide Application Range

Ideal for a diverse array of industrial processes, from HVAC to chemical duties.

High Efficiency & Great Value

Advanced technology and innovative design ensure optimal performance and cost-effectiveness.

Full Customization

A large portfolio of plates allows for perfect tailoring to specific thermal and pressure needs.

Easy Maintenance & Service

Gasketed design allows for easy opening, cleaning, inspection, and plate addition or removal.

Robust & Reliable

Built with high-quality materials for long service life and dependable operation under various conditions.

Compact Footprint

Provides a high heat transfer surface area in a relatively small and space-saving unit.

Technical Specifications

Type

Gasketed Plate Heat Exchanger (PHE)

Plate Materials

AISI 304/316 Stainless Steel, Titanium, and other alloys.

Gasket Materials

NBR, EPDM, Viton for compatibility with different media and temperatures.

Design Pressure

Up to 25 bar (standard range)

Design Temperature

Up to 180°C (depending on gasket type).

Connection Types

Threaded or Flanged ports.

Installation & Control

Modular Assembly

Frame and plate pack are assembled on-site, allowing for flexibility in transport and setup.

Flow Configuration

Can be arranged for single-pass or multi-pass flow for optimal thermal performance.

Mounting

Can be installed on a base frame or foundation, often in a horizontal orientation.

Maintenance Access

The movable pressure plate allows for easy opening without disconnecting piping.

Process Adjustment

Performance is modified by adjusting the number of plates or the flow rate.

Use Cases

- District Heating Networks

- Chemical & Process Industries

- Marine & Offshore

- Food & Beverage Production

- HVAC for Large Buildings

Product brochure

User Manual

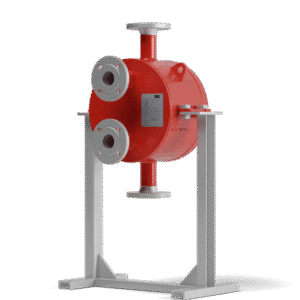

Related Products

Related products

- Heat Exchangers

Welded heat exchangers

- Heat Exchangers

Brazed heat exchangers